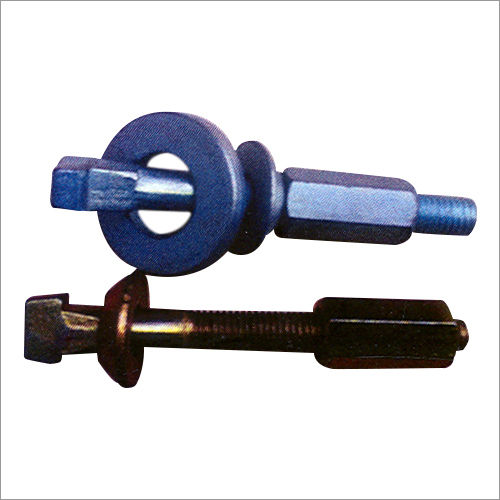

Vibrating Screening Machine Components

Product Details:

- Size Standard & Customized

- Features Corrosion resistant, precision engineered, easy installation, high strength

- Lubricating System Grease lubricated bearings

- Motor Power 0.5 HP to 10 HP, depending on component

- Usage & Applications Industrial screening, mining, chemical, food processing, pharmaceuticals

- Noise Level Below 75 dB

- Diameter 200 mm - 2000 mm (for round components)

- Click to View more

X

Vibrating Screening Machine Components Price And Quantity

- 100 Piece

Vibrating Screening Machine Components Product Specifications

- Standard & Customized

- Varies as per component, 5 kg - 100 kg approx.

- 3 kW - 15 kW (varies with machine size)

- Atmospheric

- Electric

- 220V/380V/415V

- 0.5 HP to 10 HP, depending on component

- As per component, typically 500 mm - 2500 mm (L)

- Grease lubricated bearings

- Corrosion resistant, precision engineered, easy installation, high strength

- Below 75 dB

- 200 mm - 2000 mm (for round components)

- Vibrating Technology

- Mild Steel, Stainless Steel

- Industrial screening, mining, chemical, food processing, pharmaceuticals

- Painted/Polished/Galvanized

- Vibrating Screening Machine Components

- Round, Rectangular

- Silver, Grey, Blue, Custom

- Customized, usually up to 400 TPH

- Smooth, Matte or Mirror

- Motor Driven, Vibratory Motor

Vibrating Screening Machine Components Trade Information

- Cheque

- Customized Per Month

- 1 Week

- Australia, Eastern Europe, Western Europe, Central America, Middle East, South America, Asia, North America, Africa

- All India

- ISO 9001:2008

Product Description

Discover premier savings and remarkable performance with our Vibrating Screening Machine Components. In demand across various industries, these best-in-class components feature select mesh types perforated, woven wire, polyurethane, and stainless steel. Choose bolted or welded connection types for versatility and quick replacement, fully compatible with standard machines. With temperature resistance up to 120C and engineered for seamless operation (50/60 Hz), our components guarantee extended service life and effortless installation. All spare parts are readily available. Experience high strength, corrosion resistance, and superior technology packaged for your preferred application. Exporters, importers, manufacturers, suppliers, and traders across India trust our products for their precision and durability.

Tailored Performance Across Industrial Applications

Vibrating Screening Machine Components are expertly engineered for industrial screening in sectors such as mining, chemicals, food processing, and pharmaceuticals. Their adaptable surfacessuitable for round or rectangular screensallow usage in single or multi-deck systems. Standout features include corrosion resistance, high strength, and precision engineering. With options for smooth, matte, or mirror finishes, these components deliver optimal results on various materials and ensure operational reliability in demanding industrial environments.

Payment Terms, Domestic Markets, & Secure Packaging

Estimate your expenditure with easeflexible payment terms are available for streamlined transactions. Our main domestic market spans across India, supporting regional and national exchange of goods. Packaging details are prioritized for secure delivery: every component is export-standard packed in wooden cases or boxes, minimizing risk during transport. Whether youre looking to replace, expand, or upgrade, our careful packaging and reliable distribution support swift, safe, and cost-effective exchanges for your screening equipment.

Tailored Performance Across Industrial Applications

Vibrating Screening Machine Components are expertly engineered for industrial screening in sectors such as mining, chemicals, food processing, and pharmaceuticals. Their adaptable surfacessuitable for round or rectangular screensallow usage in single or multi-deck systems. Standout features include corrosion resistance, high strength, and precision engineering. With options for smooth, matte, or mirror finishes, these components deliver optimal results on various materials and ensure operational reliability in demanding industrial environments.

Payment Terms, Domestic Markets, & Secure Packaging

Estimate your expenditure with easeflexible payment terms are available for streamlined transactions. Our main domestic market spans across India, supporting regional and national exchange of goods. Packaging details are prioritized for secure delivery: every component is export-standard packed in wooden cases or boxes, minimizing risk during transport. Whether youre looking to replace, expand, or upgrade, our careful packaging and reliable distribution support swift, safe, and cost-effective exchanges for your screening equipment.

FAQs of Vibrating Screening Machine Components:

Q: How do I select the appropriate mesh type for my application?

A: You should consider the material being processed, required separation size, and operating environment. For abrasive or corrosive materials, stainless steel or polyurethane meshes offer enhanced durability, while woven wire or perforated meshes are ideal for general screening needs.Q: What is the replacement process for these screening machine components?

A: Our components are interchangeable with standard machine parts. Simply match specifications and follow easy installation procedures; onsite support is optional if further assistance is needed. The process is designed to minimize downtime and ensure seamless integration.Q: Where can I use these vibrating screening machine components?

A: These components are suitable for use in mining, chemical, food processing, and pharmaceutical industries. Compatible with both single and multi deck screening systems, they support a variety of industrial applications and operating environments.Q: What benefits does the corrosion-resistant feature provide?

A: Corrosion resistance significantly extends service life, reduces maintenance needs, and maintains operational efficiency. This feature is especially valuable in industries exposed to harsh chemicals or moisture, ensuring dependable long-term performance.Q: When should I consider exchanging or upgrading my screening components?

A: Consider exchanging or upgrading your components when experiencing decreased efficiency, damage, excessive noise, or after several years of continuous usage. Regular maintenance checks can help estimate the optimal replacement or upgrade period.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email