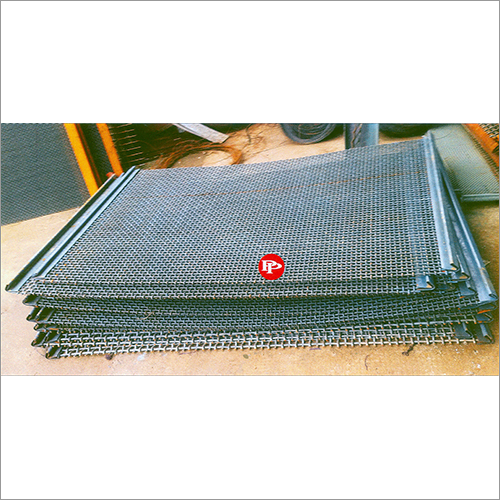

Double Crimped Wire Screen

Product Details:

- Surface Finish Smooth, Rust-resistant

- Usage & Applications Mining, Quarrying, Construction, Aggregates, Screening and Sieving

- Features High durability, Corrosion resistant, Rigid construction, Easy installation

- Size 0.5 mm to 100 mm aperture or as specified

- Noise Level Silent/No Noise

- Capacity Depends on screen opening and application

- Shape Rectangular or Square

- Click to View more

X

Double Crimped Wire Screen Price And Quantity

- 100 Piece

Double Crimped Wire Screen Product Specifications

- Customizable as per requirement

- Varies depending on size and mesh

- 0.5 mm to 100 mm aperture or as specified

- Double Crimped Wire Screen

- Depends on screen opening and application

- Rectangular or Square

- Wire diameter from 0.5 mm up to 12 mm

- Silent/No Noise

- Smooth, Rust-resistant

- Mining, Quarrying, Construction, Aggregates, Screening and Sieving

- Metallic Grey/Silver

- Double Crimped Weaving

- Manual/Mechanical

- High durability, Corrosion resistant, Rigid construction, Easy installation

- Galvanized or Uncoated

- High-Carbon Steel, Stainless Steel, Mild Steel

Double Crimped Wire Screen Trade Information

- Cheque

- Customized Per Week

- 1 Week

- Australia, Eastern Europe, Western Europe, Middle East, South America, Asia, Central America, North America, Africa

- All India

- ISO 9001:2008

Product Description

Double Crimp Screen

This type of mesh has the wire pre-undulated with strict steps in order to obtain regularity in the mesh.

Due to its high percentage of screening surface, they are used to classify, with great precision and a high performance materials that do not have a tendency to block.

The high resistance to traction of the steel used allows obtaining a great resistance to vibration and a long service time.

Exceptional Strength and Temperature Resistance

These double crimped wire screens are engineered for heavy-duty usage in challenging environments. High-tensile wires and double crimp weave provide exceptional rigidity and durability. The stainless steel variant resists temperatures up to 500C, making it ideal for operations involving extreme conditions. Coupled with corrosion-resistant treatments, these screens deliver reliable performance across various industries.

Customizable for Versatile Applications

Customize your mesh size, dimensions, finish, and material to suit precise operational requirements. Available in rectangular or square shapes, with wire diameters from 0.5 mm up to 12 mm, they cater to a variety of screening and sieving applications in mining, construction, and aggregate processing. Opt for galvanized or uncoated finishes as your environment demands.

Hassle-Free Installation and Long Service Life

Choose from multiple edge and connection typesplain, locked, or bolted edgesalong with clamps, hooks, or welding for attachment. Each screen is fabricated for easy installation and minimal maintenance, shipped as rolls or flat panels with protective wrapping. The rigid construction ensures a silent, reliable operation with remarkable longevity.

FAQs of Double Crimped Wire Screen:

Q: How is the double crimped wire screen installed in different screening systems?

A: Installation options include clamps, hooks, or welding based on your systems design. The screens edges can be supplied as plain, locked, or bolted for compatibility, ensuring straightforward and secure fitting for both new and retrofit applications.Q: What factors determine the choice of mesh size and material for specific projects?

A: Mesh size, ranging from 0.5 mm to 100 mm, and wire materialhigh-carbon steel, stainless steel, or mild steelare selected based on the nature of materials to be screened, expected load, environmental conditions, and desired service life. Customization is available per your operational requirements.Q: When should stainless steel screens be used over other materials?

A: Stainless steel variants are recommended for operations that involve exposure to high temperatures (up to 500C), corrosive substances, or where longevity and minimal maintenance are essentialmaking them suitable for demanding mining and industrial environments.Q: Where are double crimped wire screens typically used?

A: They are widely utilized in mining, quarrying, construction, aggregate processing, screening, and sieving applications due to their durability and high capacity. Their robust performance and versatility make them a favorite for heavy-duty and silent operation needs.Q: What customization options are available for these wire screens?

A: You can customize mesh opening size, dimensions, material type, surface finish, and edge style. This ensures optimal fit and performance tailored to your equipment and project requirements, supporting a range of industrial applications as an exporter, importer, manufacturer, supplier, and trader.Q: How does double crimped weaving benefit screening efficiency?

A: Double crimped weaving provides extra rigidity, preventing displacement of wires under heavy loads. This maintains consistent mesh openings, improves screening accuracy, extends service life, and allows for smoother operation with minimal maintenance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email